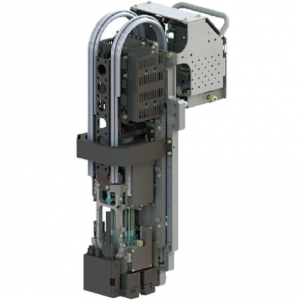

Yamaha YRM20 – P & F

Premium high speed pick and place machine

Introduction

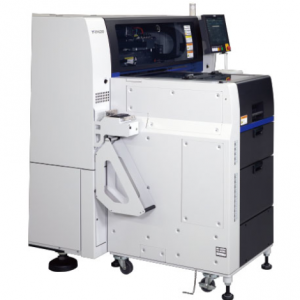

Whether it is high mix or high volume production, our answer is the Yamaha YRM20. Renewed and improved user interface, production preparation and transition support. Premium quality, focused on productivity.

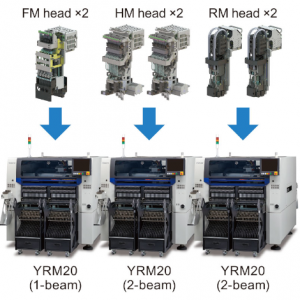

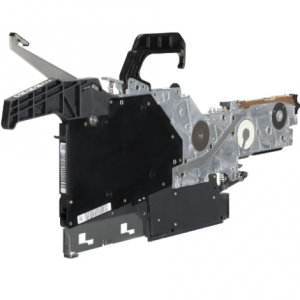

For production with high speed requirements, we recommend the RM Rotary head created by the combination of YSM and Σ technologies, with which the equipment can reach speeds of up to 115,000 CPH with high-speed feeder support. The RM head is able to transfer common parts 98% with an incredible 25um accuracy!

When we focus on the variety of parts that can be planted, we recommend the improved universal HM head, with which we can plant everything from the smallest parts to odd-shaped parts with the same precision and at an outstanding speed (98,000 CPH).

The main characteristics of the YRM20 platform:

- Win 10 platform

- Improved servo system

- Increased planting panel size and transport speed

- Clean user interface

- Advanced new part detection

- Nozzle level management

Of course, this type of machine, like all other Yamaha machines, is part of the One Stop Smart Solution (complete Yamaha production line) concept.

Details

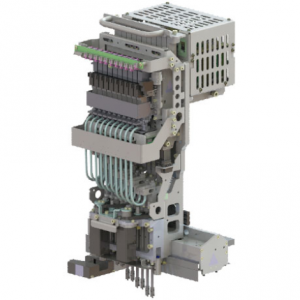

- 2 beam 2 head design

- Insert parts: from 0201 mm 55 x L 100 mm (H15 mm)

- Increased planting quality by using a “Low-impact nozzle”.

- Modern user interface

- High speed feeder to serve RM head speed

- Improved DUAL Stage Conveyor System

- Insertion accuracy ±0.025mm Cpk≧1.0

- Improved teachable intelligent component recognition system

- Side camera

- Pipette cleaning station

- Touch screen display

- 128 interchangeable feeders 8 mm feeder space

Parameters

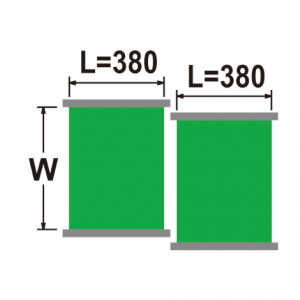

- Size of panel that can be inserted:

- L 50 x W 50 to L 810 x W 510 mm

- Insertion speed (IPC9850):

- 2x RM head: 115.000/78.500 CPH

- 2x Inline FM head: 98.000/68.000 CPH

- Dimensions: 1374(width) x 1948(depth) x 1445(height) mm

- Weight: 2250 kg

- Power supply: 3~ 400 V, 50/60 Hz, CEE 16 A

Image gallery