JBC Hot Air stations

The highest quality contactless desoldering

Introduction

Hot Air Station – a tool for reworking all types of SMDs

Hot Air Stations heat up quickly and evenly to reflow the solder to either attach or remove the component to or from the PCB. Hot air is delivered through the hose, making it possible to rework any type of SMDs.

JBC Hot Air Stations have the capability of controlling precise temperature and airflow.

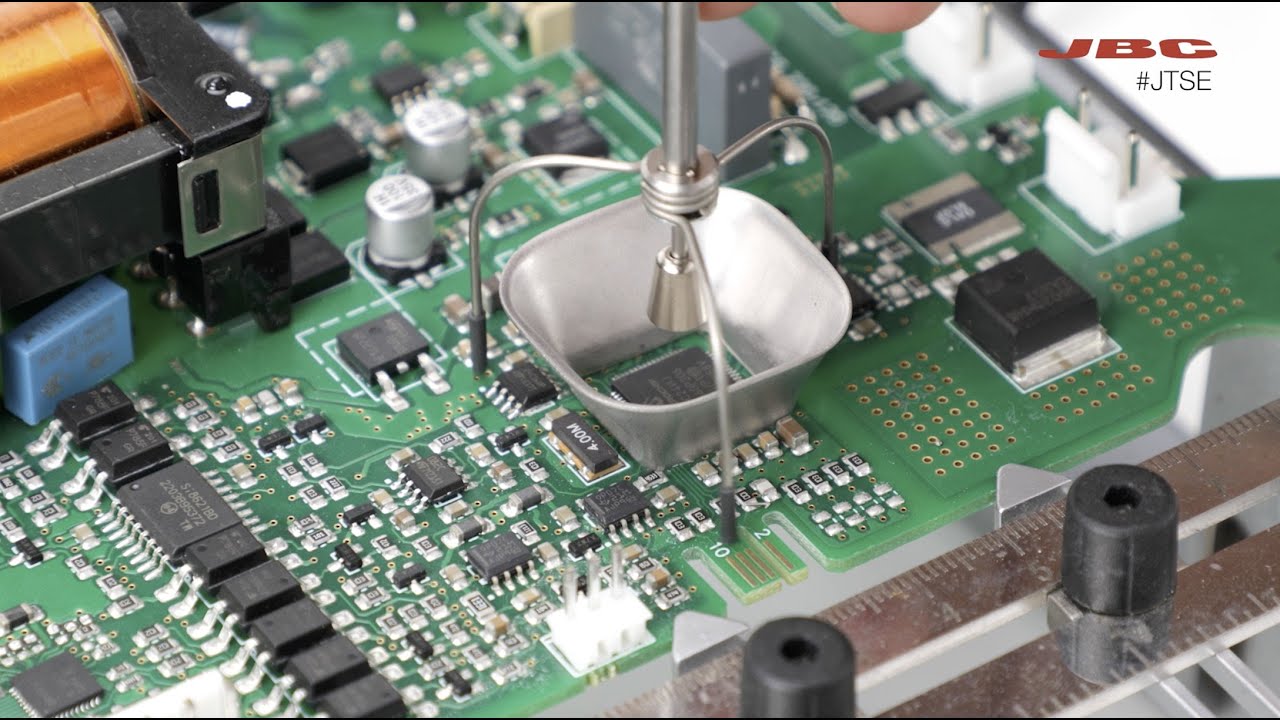

Desoldering process using JBC Hot Air Stations

1. Positioning

Choose the protector and tripod which best fits the component. Activate the suction pump and push the extractor to the component.

2. Heating

While you apply heat to the component, the surrounding elements are protected.

3. Extracting

Automatic withdrawal of the desoldered component.

Personalize your soldering process parameters with JBC Profiles:

In order to work with profiles, it is essential to use Rework Arms.

Up to 25 configurable temperature profiles can be created and stored to avoid termal shock to specific components during the rework process.

Using Thermocouple Type K

Attach an external Type K Thermocouple and TC so that you are able to set either a Regulation or Protection Mode.

Regulation Mode provides a high-precise close-loop to automatically maintain the external Thermocouple (TC) temperature.

Protection Mode is used to protect any heat sensitive areas or components. The station cuts the air supply off when the TC temperature is reached.

Thermocouple Type K is included in TESE & JTSE Stations.

Details

JTSE Hot air station

JTSE is a powerful hot air station capable of refinishing all types of SMDs.

The combination of the exclusive JBC hot air system with protectors, tripods and extractors ensures easy and safe desoldering of the component.

Connecting an external thermocouple provides high-precision closed-loop control of the component and PCB during the finishing process and can be used to protect the component or a specific area of the PCB.

Like all JBC stations, the JTSE has a menu with more than 10 parameters for adjusting the control unit.

JNA Precision hot air station

JNA is the only hot air station that does not affect nearby components during SMD finishing.

It is the perfect station for easy and precise finishing of components as small as 01005, even under a magnifying glass.

Includes:

• NH high precision heating hose set that works with the J125 cartridge range and the J325 cartridge range.

• T260 Pick & Place for easy placement and removal of components thanks to the built-in suction pump.

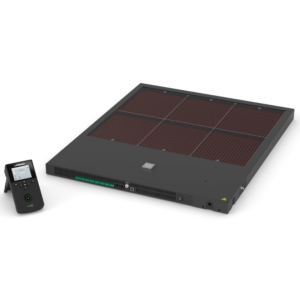

SRS SMD Rework System

SRS SMD Rework System provides full control over SMD rework processes.

- JTSE Hot Air Station controls the rework task using temperature and air flow profiles.

- RWS Rework Arm supports the JTT Heater Hose Set, allowing handsfree operation.

- PHSEK Small Preheater Set comes with PHSE Small Preheater and PHSS Small PCB Support.

A variety of Protectors, Extractors and Tripods are included.

Options

JBC Hot Air Stations offer three different Hose Sets, depending on your needs:

- NH High-PrecisionHeater Hose Set

- TET Precision Heater Hose Set

- JTT Heater Hose Set

The perfect combination of heating element and nozzles allows you to concentrate the heat on the selected component.

Our range of hot air tools allows you to repair all types of SMDs quickly and safely, even the biggest QFPs and PLCCs.

- Cartridges for NH

It works with JNA High-Precision Hot Air Station, which allows regulation of both flow and temperature at very low levels.

- Nozzles for TET & JTT

Nozzles direct the heat to a particular area so that adjacent components are protected. The range features different shapes and diameters to regulate the hot air flow. All models are easily interchangeable.

Accessories for the desoldering process:

- Extractors, Tripods & Protectors

- Pick & Place

- Rework Arms

Parameters

JTSE Hot air station

- Maximum power – 700 W

- Adjustable temperature – 150 to 450 °C / 300 to 840 °F

- Air flow regulation – 5 to 50 SLPM

- Vacuum – 30% / 228 mmHg / 9 inHg

- Profiles – 25 (up to 10 steps each), 1 preset profile

- Type K TC connector – 1 for control and protection

- ESD safe – Supports ANSI / ESD S20.20-2021

- Potential equalization – Optional connection to EPA

- USB-A – Update firmware, graphics and profiles

- USB-B – PC communications

- RJ12 connector – Connection for remote control or FAE smoke extractor

- Pedal connector – Tool control

JNA Precision hot air station

- Total power – 70 W

- Adjustable temperature – 150 to 450 °C / 300 to 840 °F

- Air flow regulation – 0.15 – 2.5 SLPM

- Vacuum – 53% / 397 mmHg / 15.6 inHg

- ESD safe – Supports ANSI / ESD S20.20-2021

- Equalization of potential – Connection with EPA

- USB-A – Update firmware, graphics and profiles

- USB-B – PC communications

- RJ12 connector – Connection for remote control or FAE smoke extractor

- Pedal connector – Tool control

SRS SMD Rework System

JTSE Control Unit

- Peak power – 700W

- Selectable temperature – 150 to 450 °C / 300 to 840 °F

- Air flow regulation – 5 to 50 SLPM

- Vacuum – 30% / 228 mmHg / 9 inHg

- Profiles – 25 (up to 10 steps for each), 1 preset profile

- Type K TC connector – 1 for Control & Protection

- ESD safe – Meet ANSI / ESD S20.20-2021

- Equipotential bonding – Connection to EPA

- USB-A – Firmware update; Graphics and profiles

- USB-B – PC communications

- Robot connector – Remote control or FAE Fume Extractor connection

- Pedal connector – Tool control

PHSE Preheater

- Peak power – 600W

- Selectable temperature – 50 to 250ºC / 120 to 482ºF

- Heating area

- 65 x 135 mm / 2.6 x 5.3 in – 1 zone

- 130 x 135 mm / 5.1 x 5.3 in – 2 zones

- Type K TC connector – 4 for control & protection

- Profiles – 22 (up to 16 steps for each), 3 preset profiles

- Maximum work time – 600 min. or indefinite

- ESD safe – Meet ANSI/ESD S20.20-2021

- USB-A Firmware update; Graphics and profiles

- USB-B – PC communications

- Robot connector – Remote control

- Aux. connector – Console connection

- Pedal connector – Connect a pedal (ref. P-005) to control the heater