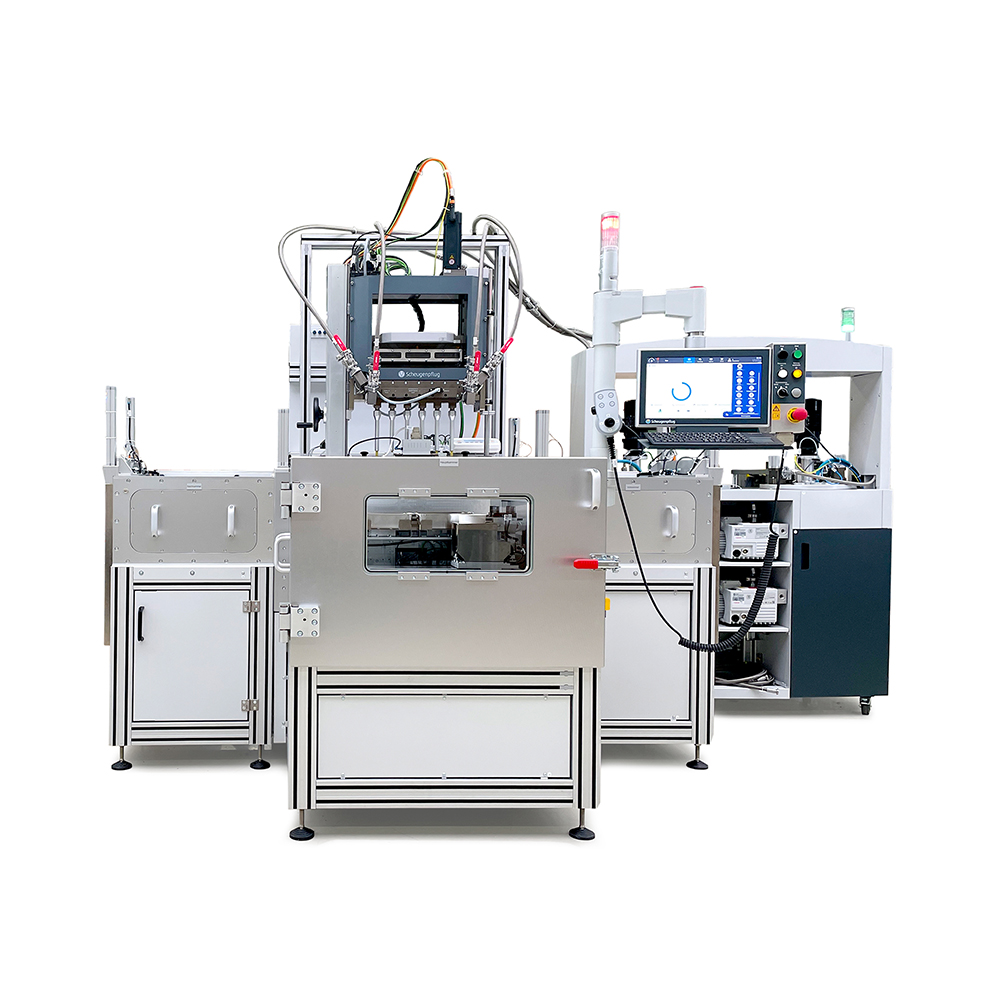

Scheugenpflug VDS vacuum chamber series

Vacuum chamber series

Introduction

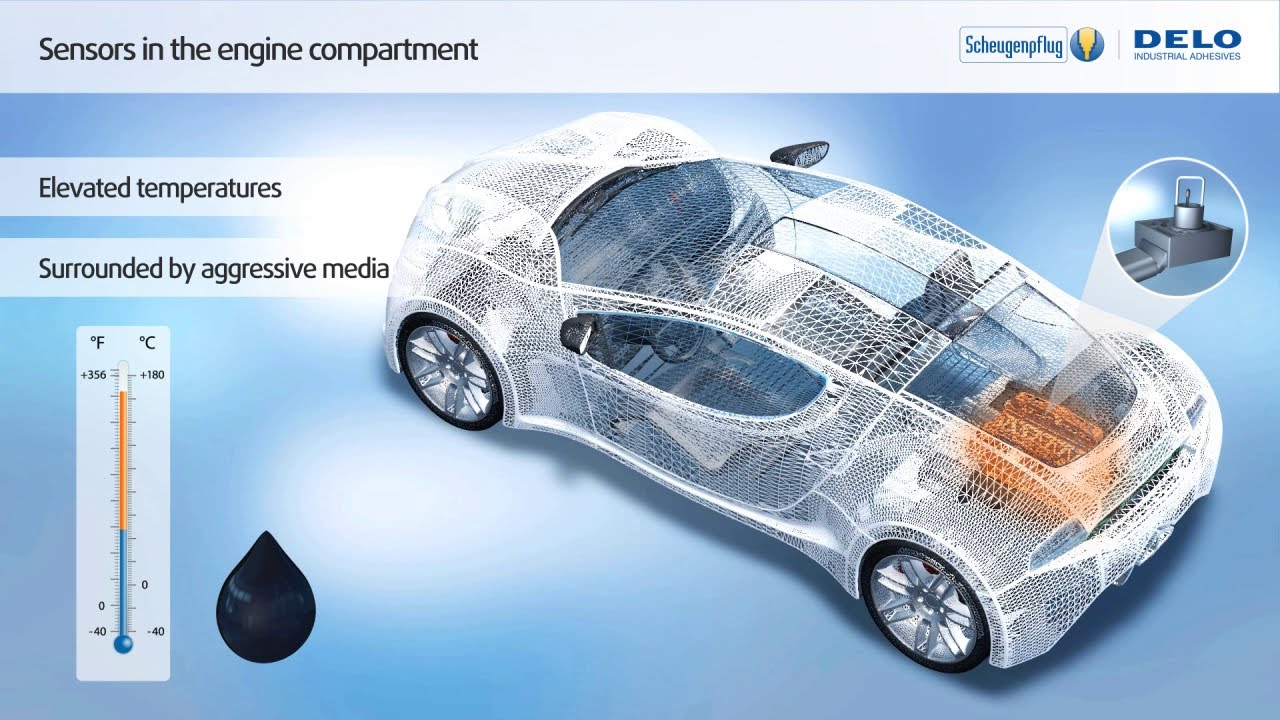

Scheugenpflug is the market leader in potting solutions from prototyping to inline mass production. The Scheugenpflug VDS vacuum chamber series provides excellent, bubble-free, homogeneous dispensing quality for filling coils, sensors or motors with self-leveling materials. The VDS series, with its large working area, Scheugenpflug’s versatile automation solutions and single or multi-mixing tube designs is the perfect solution for those who value high dispensing quality as well as short cycle times.

Details

- Bubble-free even dispensing

- High quality low scrap rate

- Air-tight filling of products (coils, other parts), even with complex geometries

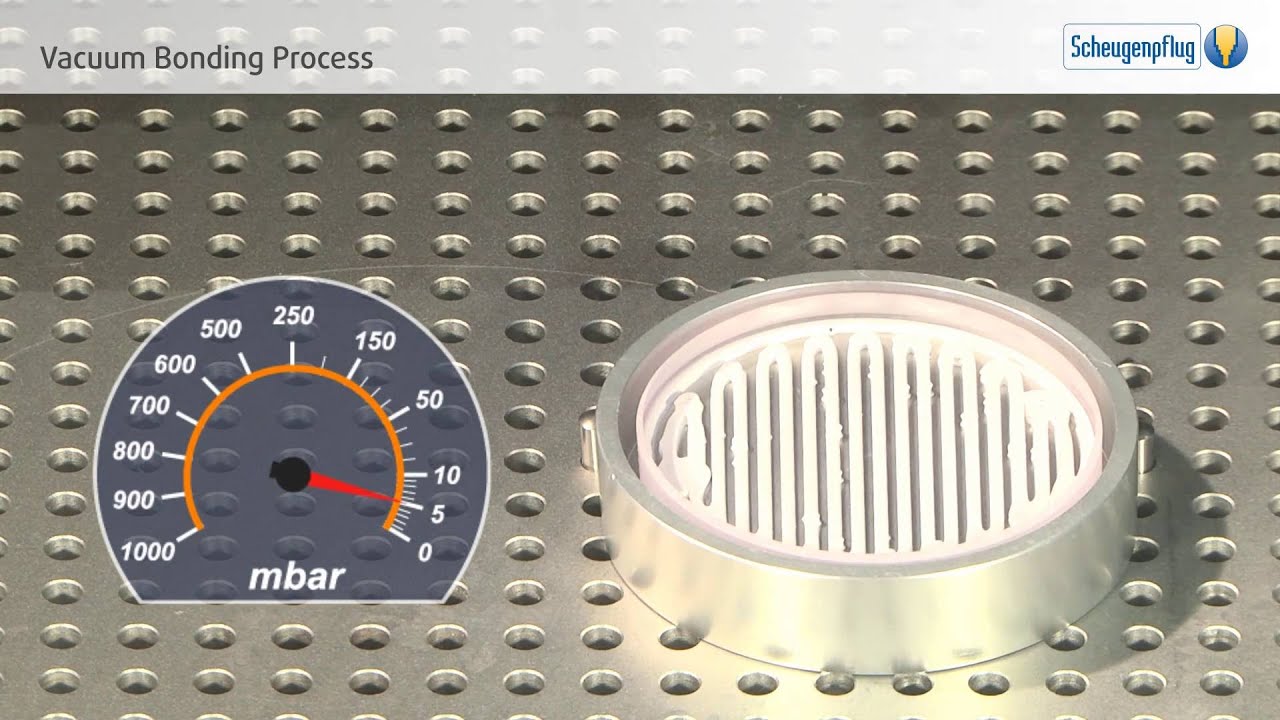

- Vacuum bonding, inclusion-free thermal paste application without mechanical stress on components

- Application specific vacuum generation (from 500 to 5 mbar)

- Vacuum material preparation unit LP804 required

- Low operating costs

- Robust construction

Product Options

VDS Series

- Various equipment:

- VDS Basic; Universal; Power

- Working space 300 x 300 or 420 x 420 mm

- From 1 to 12 mixing tubes

- XYZ axis system maximum stroke (mm): 920 x 85 x 200

- Product, mixing tube and dispensing head heating

- Waste cup

- UVIS5 control unit

- 5 mbar vacuum value

- Custom VDS:

- Inline vacuum chamber

- multi vacuum chamber to reach the shortest cycle time requirements