PBT MiniSwash

A budget stencil cleaning machine

Introduction

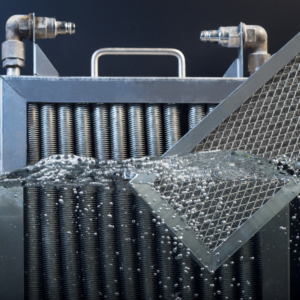

The PBT MiniSwash II is suitable for the removal of metal stencil plates and frames, solder paste or adhesive residues and small quantities of PCBs used in SMT production. The performance/price ratio of the stencil washer is outstanding on the market. Thanks to its special design, it can safely clean both PumpPrint and stencils thinner than 100 microns.

Details

Washing stents, misprints, knives

- Works with water-based detergents

- Stainless steel chamber and casing

- High pressure cleaning, spray in air technology

- Double-sided balanced spray pressure with synchronized rotary arms

- Hot air drying process with programmable temperature and extraction

- Extremely low detergent consumption

- Controlled parameters

- Cleaning time

- Warm air drying time

- Monitoring the cleaning fluid level

- Monitoring the quality of flushing fluid

- Monitoring mechanical filter status

Product Options

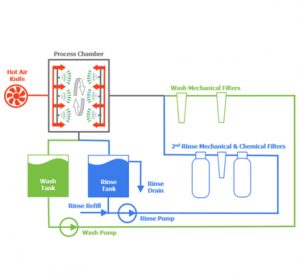

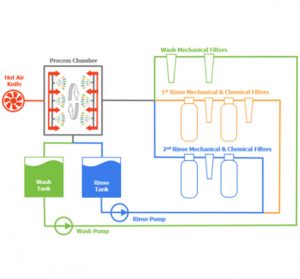

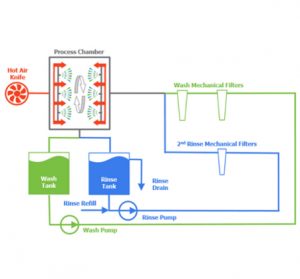

- Multiple configurations (washer, washer-rinse and washer-rinse-rinse)

- Connectivity to an external water source

- Zero Drain, drainless operability in the production area

- Connectable to central extraction

- Lighting tower

- Stencil and product barcode scanning

Parameters

Typical cycle times:

- Stencil 10-15 minutes

- Mounted panel 30 minutes

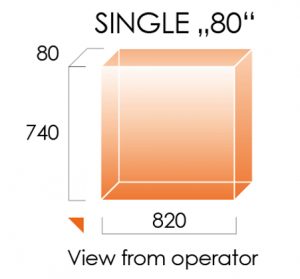

Max. washable size: 740 x 740 x 80 mm

Equipment dimensions: 1 503 x 777 x 1 191 mm (W x H x D), 250 kg