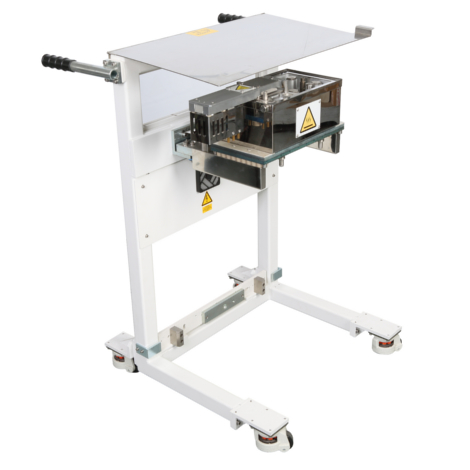

Handex

Designed with LEAN manufacturing requirements in mind, the flexible HANDEX selective soldering equipment offers high speed at an affordable price. Equipped with the smallest 1.5 mm micro nozzle available on the market, any soldering task can be solved.

- Details

- Parameters

- Options

- Loading time up to 2 seconds with a rotating twin worktable

- Off-line operation

- Drop-jet flux application unit

- Visual teaching system based on panel image (Jpeg or Gerber)

- Soldering with shielding gas

- Wetted AP1 nozzle / JetWave mini-jet / multi-chimney solution

- Hot wave height measurement and control unit

- Lead or lead-free design

- PillarPAD offline programming software

- Equipment dimensions: 1627 x 1900 x 2508 mm (M x W x H)

- Max. panel size: 457mm x 508mm

- Hot tub capacity: 15 kg (standard) / 25 kg (large)

- Nitrogen consumption: 30-100 litres/min (depending on nozzle configuration)

- Required Nitrogen purity: 99.995% or cleaner

- Required Nitrogen pressure: 5 bar

- Required air pressure: 5 bar

- Power supply: 230V, 50/60 Hz, up to 10.5 kVA (depending on the configuration of the equipment)

- O² ppm monitoring system

- N² flow meter

- Flux flow measurement unit

- Automatic solder dispenser and solder bath level control

- Solder roll and hot tub identification system

- Encoder feedback on X, Y and Z axes

- Laser panel curvature measuring unit

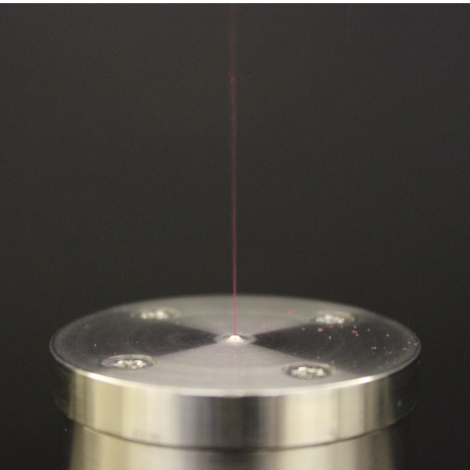

- Patented 1,5 mm nozzle

- Large hot tub with double nozzle

- Top and/or bottom infra preheating unit

- Closed feedback preheating with pyrometer

- Position point detection and correction system

-

Microphone nozzle

1.5mm micro nozzle for the most difficult solder points

-

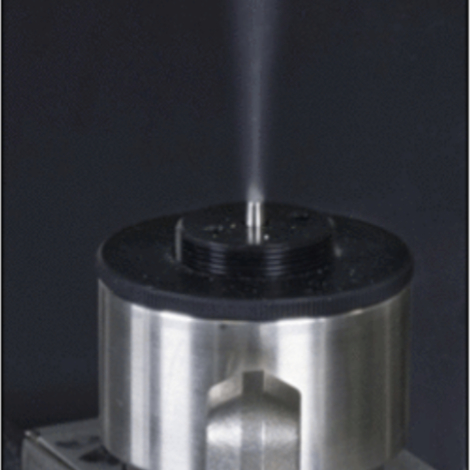

DropJet fluxer

Selective and precise flux application

-

Ultrasonic fluxer

-

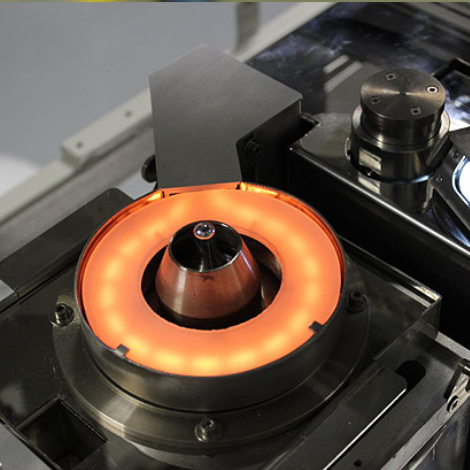

Ringheater

Fast and selective preheating option

-

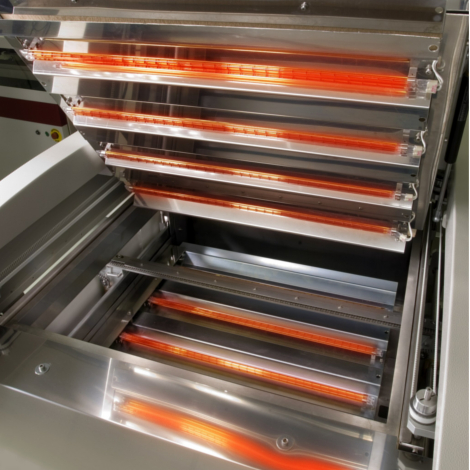

PREHEATING

Bottom and/or top preheating configurable

-

PREHEATABLE HOT TUB

Quick-change hot tub station with offline heating

-

PANEL CURVATURE TEST

Correction of soldering according to the curvature of the product

-

Nitrogen analyser

Automatic measurement of shield gas purity

VIDEOS

Pillarhouse Handex

High speed offline soldering machine developed for Lean manufacturing requirements.