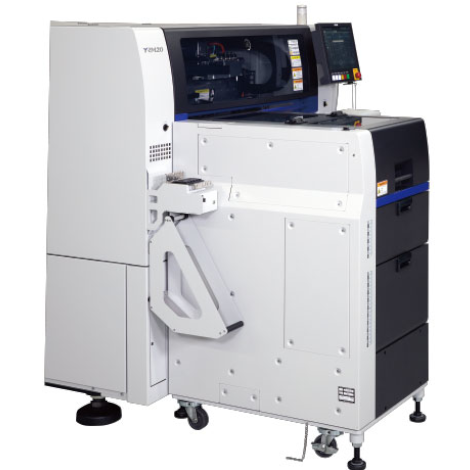

YRM20 – New update

A premium, high-efficiency, modular SMT pick and place machine

Yamaha will start selling the YRM20 equipped with the most innovative technologies from April 2020. In terms of its speed and capabilities, it serves the high-mix, high-volume market in a similar way to its predecessor.

With its newly developed rotary implant head (combining YSM & S technologies) and high-speed feeders, it is capable of speeds up to 115,000 CPH. This head can fit 98% common parts with incredible 25um precision.

In cases where the requirement is to also plant the remaining component type of 2%, we recommend the improved universal HM head, which allows fast planting with the same accuracy at 98,000 CPH.

In addition to the above, the new platform has new features such as:

- Win 10 platform

- Advanced servo system

- Increased planting panel size and transport speed

- Clean up the GUI

- Improved recognition of new parts

- Improved nozzle management

Of course, this type of machine, like all other Yamaha machines, is part of the Total Line Solution concept.

- Details

- Parameters

- Options

- 2-beam, 2-head design

- Installation parts: from 0201 mm 55 x D 100 mm (H15 mm)

- Increased planting quality by using a "low impact nozzle".

- Modern user interface

- A high-speed feeder that serves the speed of the RM head

- Advanced DUAL Stage transport system

- Implantation accuracy ±0.025 mm Cpk≧1.0

- Improved system for recognizing intelligent parts that

- can train

- Side camera

- Pipette cleaning station

- Touch screen

- 128 replaceable slots for 8 mm

Part of Yamaha Total Line Solution (complete SMT production line)

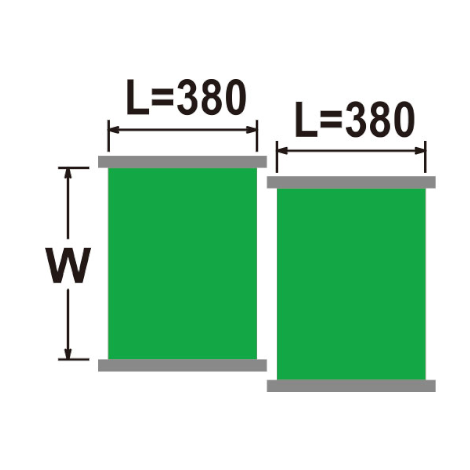

- Insertable board size:

- From L 50 x W 50 to L 810 x W 510 mm

- Implantation speed (IPC9850):

- 2k RM head: 115,000/78,500 CPH

- 2k Inline FM head: 98,000/68,000 CPH

- Dimensions: 1374 (width) x 1948 (depth) x 1445 (height) mm

- Weight: 2250 kg

- Network: 3~ 400 V, 50/60 Hz, CEE 16 A

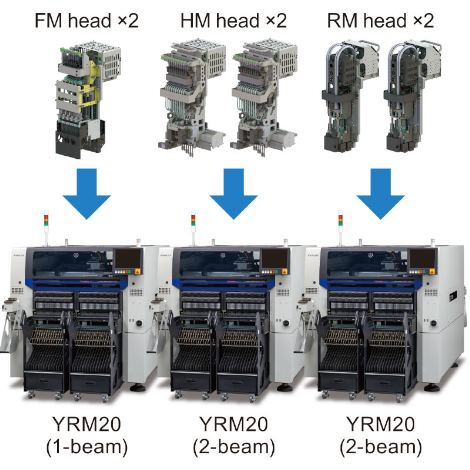

- One (1) or two (2) head design

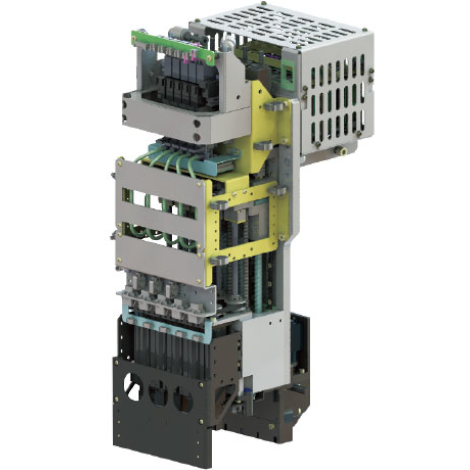

- Two-stage option (two planting segments inside the machine)

- Unit of coplanarity

- Automatic panel support assignment

- Auto-load feeder (fewer splices)

-

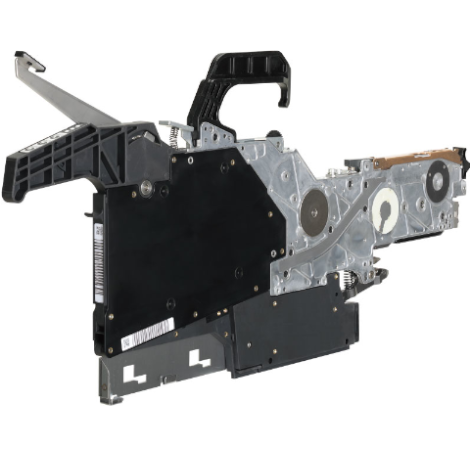

zsr feeder

-

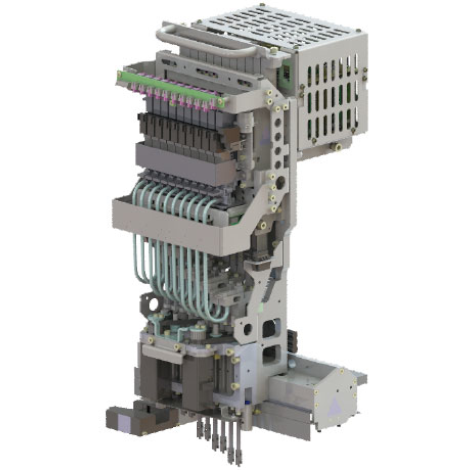

super high-speed rm head

-

Sid

-

overdrive motion

-

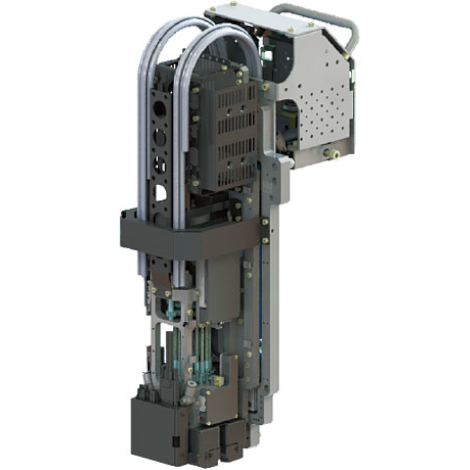

odd shaped fm head

-

High speed hm head

-

Dual-stage conveyor

-

Beam Variations