Yamaha Factory Tools

Production planning and product support

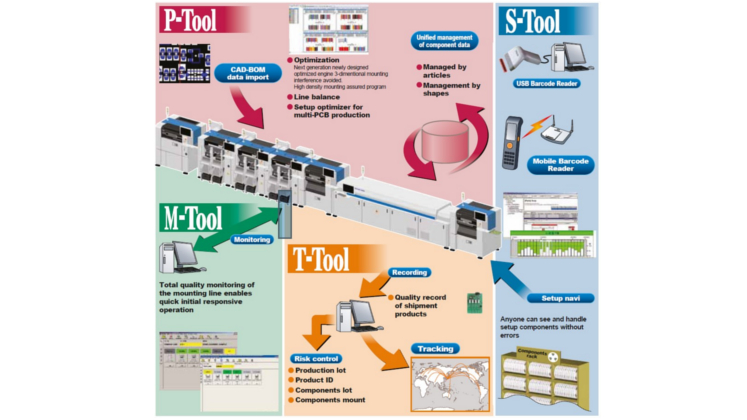

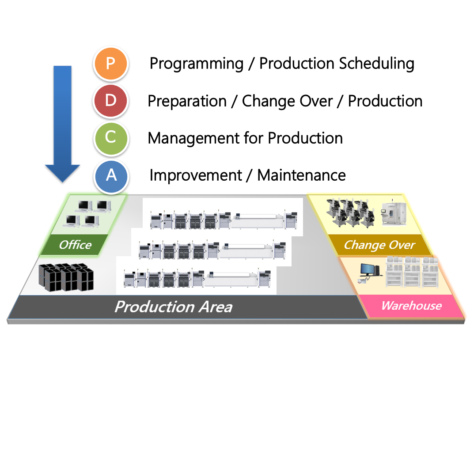

Yamaha could not fully implement the Intelligent Factory and Total Line Solution concepts without a software package that allows it to manage all of this in a centralized and user-friendly way. Watching the video below is worth more than any words, but to summarize the gist, Yamaha's solution includes the following software packages:

Data Programming Package - CAD Conversion, Virtual Duct Tape, Line Optimization, Production Planning

Line Monitoring Package - Line monitoring, remote component loss prediction

Setup navigation Package - Preparation of components, transition management

Traceability Package - Data Collection, Retrieval

IT solutions - Automatic program switching, LED binning, Adaptive feeder placement and many others

Integrated solutions - third party communication link

We would especially emphasize the possibility of active communication between machines, such as M2M connection, which can be implemented at the highest level only by manufacturers who make the entire production line available not only from one source, but from one manufacturer! Yamaha is like that.

M2M in our case:

Automatic loading of the program for the entire row

Badmark transfer

Print feedback

Feed forward

AOI feedback to the assembler

Preparation of warehouse components

- Details

-

Intelligent factory 1

-

Intelligent factory 2

VIDEOS

Yamaha Smart Factory

Yamaha is at the forefront of implementing Industry 4.0 solutions. With the new production control software package, communication (M2M) and autonomous correction functions between Yamaha machines have become more efficient than ever before.