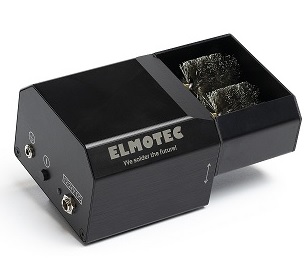

SolderSmart

Table top soldering robot

Developed and manufactured by ELMOTEC of Switzerland, the SolderSmart® soldering robot meets the highest technical standards.

Its repeatability takes production quality to a new level thanks to the high precision XYZ electric linear axes and automatic zero point calibration.

Typically used for soldering leads, connectors, THT components.

A simple plug & play solution, ready for monitoring and traceability - documenting all points of the soldering process with photos if needed.

- Details

- Parameters

- Options

- Large worktable size: 483*383mm

- Fully automatic zero calibration and solder tip measurement

- Automatic solder tip maintenance control

- Learning trigger points with an integrated camera

- Integrated industrial PC

- Rotary brush cleaning station

- High precision wire feeder - with integrated control, data logger, process parameter monitoring

- Integrated extraction device - direct extraction at the soldering head

- Working area 483×383 mm

- Stepper motor X,Y,Z drive

- Axis accuracy ± 0,02 mm

- Speed approx. 400mm/s

- Power consumption max. 10A

- Supply voltage 1x 110 VAC / 1x 230 VAC, 50-60 Hz

- Ethernet / USB / Digital I.O / HDMI

- Dimensions: 880 x 880 x 770mm (830mm with enclosure)

- Weight: 75 kg (basic model)

- Colour process monitoring camera - for real-time process tracking, traceability, alignment of pickle tip to solder points

- Protective cover - CE and ESD aspects

- Self-closing and self-opening drawer system with two drawers - while the robot is soldering on one side, the operator can change the already soldered parts on the other side

- Direct LED lighting to the work area

- Machine Vision System - automatically detects and corrects position inaccuracies

- Touch screen

- Scanner for traceability, greater process security

- Machine frame with vibration-damped rollers that can be levelled and locked

VIDEOS

SOLDERSMART® SOLDERING ROBOT WITH PICKS

Replace your manual soldering tasks with the SolderSmart® desktop solution. The SolderSmart® soldering robot meets the highest technical standards ensuring controlled and documented soldering processes.