SELECTIVE RIDER

This niche instrument is designed to test any selective soldering machine condition. With the Selective Rider, repeatable data can be collected on key machine and process parameters to ensure production stability and reliability. The instrument also measures solder height, diameter, temperature, nozzle X/Y accuracy and preheat temperature.

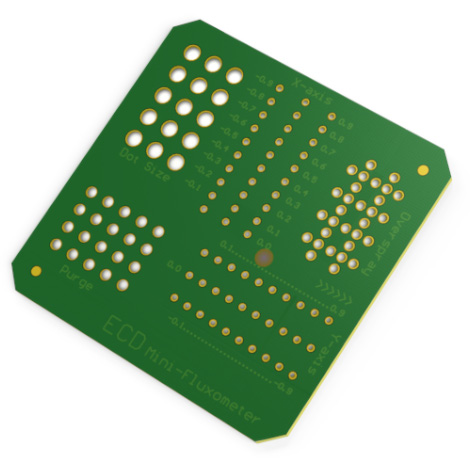

The fluxing properties (scattering pattern, X,Y position, repeatability) can be tested with the mini Fluxometer test coupon available for the fluxer type.

The machine condition test palette for continuous monitoring of equipment capabilities, detection of failures, checking the efficiency of maintenance or comparing equipment. The instrument is based on the well-known 6-channel SuperMole Gold 2 with thermal profiling instrument works.

- Details

- Parameters

- Options

-

- For use with any brand of offline or inline selective solder

- Repeatable, simple and fast machine status without test bench

- Parameters to be tested:

- Preheating temperature on the top side of the panel

- Hot gas temperature

- Hot water height

- Nozzle position in X, Y directions

- Mold diameter

- Immersion time

- Delta T when soldering

- Fluxing parameter analysis, scattering pattern, fluxer position, volume

- For both DropJet and ultrasonic spray fluxers

- Placement points are designed on the test board for automatic camera alignment equipment

- Evaluation of measurements and statistical monitoring of key process indicators (KPIs) (SPC) is done in the new Selective module of MoleMAP software

- The instrument has 6 channels SuperMole Gold 2 works with a thermal imaging sensor

- Dimensions: length 300 mm; width 200 mm; height 35.4 mm, fits in any machine, can be mounted in a frame for larger conveyor widths

- Weight: 1.72 kg

- In addition to selective soldering, we also have a solution for testing wave soldering machine condition in the WaveRider

-

SELECTIVE RIDER

6 channel Super Mole Gold2 compatible

-

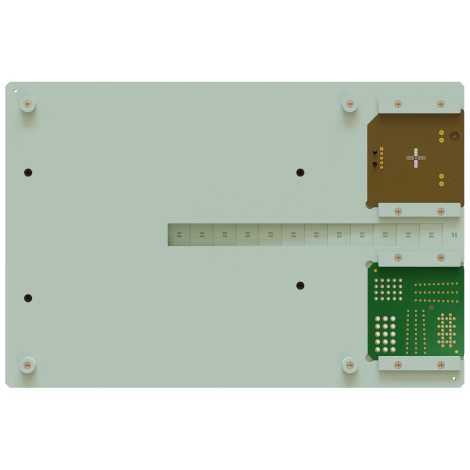

THE RIDER FROM BELOW

Height measuring ladder, nozzle position contact sensors and fluxometer test sheet

-

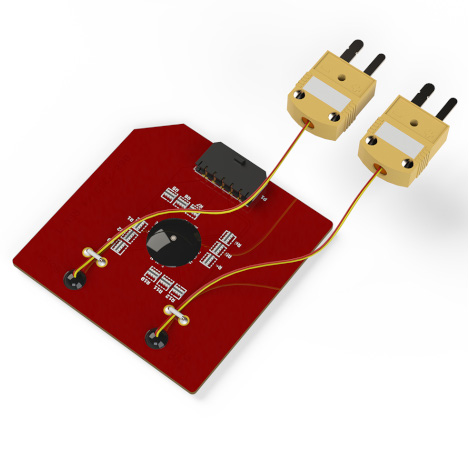

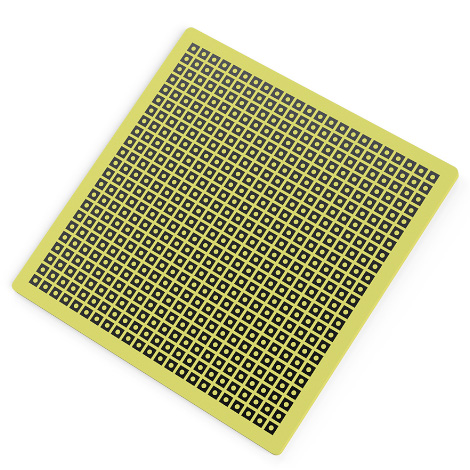

RIDER COUPON

Replaceable measuring tape

-

RIDER IN THE MACHINE

The instrument can be used in any machine with or without frame

-

MINI FLUXOMETER V-GAUGE

DropJet fluxer scattering pattern, X-Y position study

-

MINI FLUXOMETER

Spray fluxer measurement