Electrovert OmniMax/ES

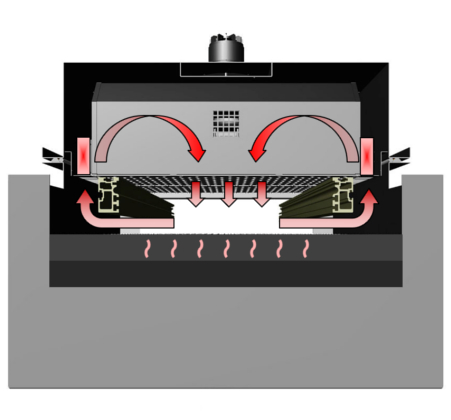

Thanks to the new IsoThermal heating zones, Electrovert reheating furnaces produce extremely precise heat transfer. Combined with the rail heating option, DeltaT of up to 1.5 °C can be achieved over the full 508 mm furnace width. And the OmniES reflow furnace sub-type with passive bottom heating offers an economical solution for projects with smaller investment budgets.

- Details

- Parameters

- Options

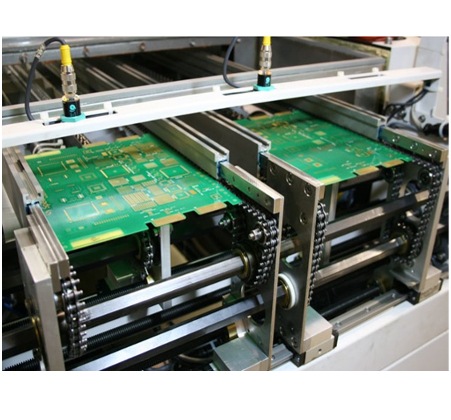

- Robust conveyer design

- Software-controlled convection per zone

- Low deltaT

- Up to 20% lower energy consumption compared to previous equipment

- ES design, economical cost-effective version with active top-side and passive bottom-side convection

- Made in USA

- 10 zone unit size: 6439 x 1367 x 1241 mm (W x H x D)

- Max. processing width: 508 mm (optional 910mm)

- 5, 7 (+2) or 10 (+3) zones

- 2685 mm or 3855 mm heated length

- Closed circuit cooling zones for nitrogen soldering

- Oxygen analyser with automatic nitrogen flow control

- Top and bottom cooling zone

- Two-track design

- Parkable central support system

- Innovative flux draining system

-

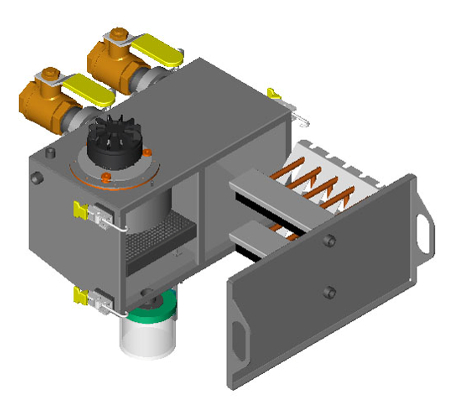

IsoThermal HEATING ZONE

The heart of Electrovert furnaces is the patented heating zones that ensure minimum deltaT

-

Heating Zone Diffusers

It ensures homogenous heat distribution inside the furnace

-

Intelligent Flux Control

Custom flux draining system option

-

OMNIES VERSION

Passive bottom preheating solution for an economical initial investment

-

DUAL LANE OPTION

VIDEOS

ELECTROVERT SOLDERING AND CLEANING PRODUCT RANGE

The US manufacturer's portfolio includes the OmniMax reflow oven, Electra wave soldering machine and the high-efficiency AquaStorm inline washer family.

ELECTROVERT REFLOW TECHNOLOGY

Robust high performance furnaces with the smallest deltaT on the market are suitable for soldering any heavy or multi-layer panel.