<трп-пост-цонтаинер дата-трп-пост-ид='5216'>СИСТЕМИ ЗА ДОЗИРАЊЕ ЗАПТИВАЧА ОД ПЕНЕ ЦЕРАФЛОВ

Системи за дозирање заптивне пене

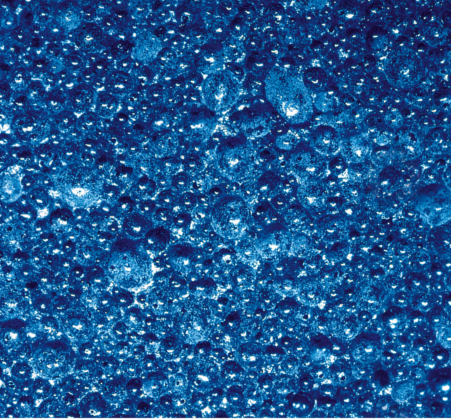

Церацон је лидер на тржишту у дозирању једнокомпонентних полиуретанских пена. ТХЕ ЦераПУР материјали имају затворену ц́елијску структуру, тако да имају одличне перформансе изолације влаге, прашине или чак звучне изолације. Уз помоц́ система за дозирање ЦераФлов може се дозирати било која сложена, чак и 3-димензионална контура. Систем је заснован на запреминском принципу и однос пене и ваздуха се може мењати према задатку.

- Details

- Parameters

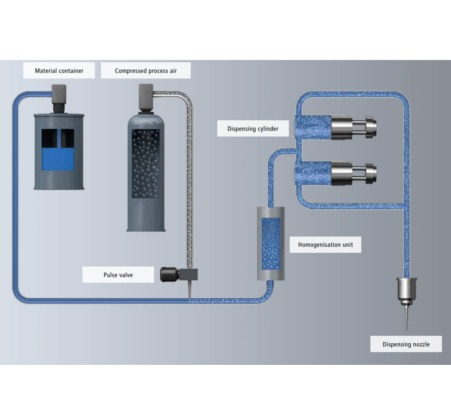

- Волуметријски систем за дозирање полиуретанске пене

- Прецизна хомогенизација мехуриц́а

- Променљиви однос ваздуха и материјала

- Могу се спојити канте од 20 литара или бурад од 200 литара

- Ниски захтеви за одржавање

- Индустријска роботска глава за дозирање или кретање производа за постизање савршене контуре

- Доу опција за континуирани проток материјала

- Чишц́ење плазма главе за постизање одговарајуц́е адхезије

- Заптивање је доступно у немачкој фабрици Церацон

- Стврдњавање

- Приближне димензије: 1.850 x 900 x 1.925 мм

- 750 кг

- Брзина дозирања 0,15 – 10,0 г / сек.

- Мешање се може променити од мешања без пене до пене са повец́ањем запремине до 5 пута

-

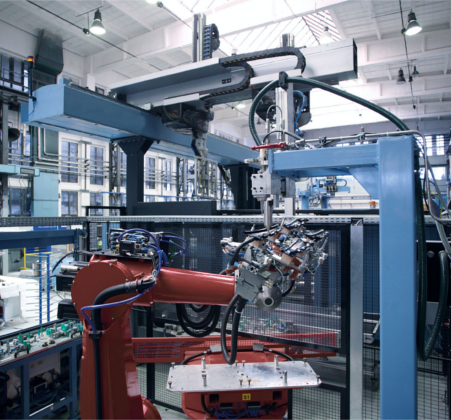

AUTOMATED UPLOAD

For complex dispensing patterns, Ceracon also offers complete solutions mounted on an industrial robot

-

STRUCTURE OF CERAFLOW

Volumetric dosing with proper homogenisation

-

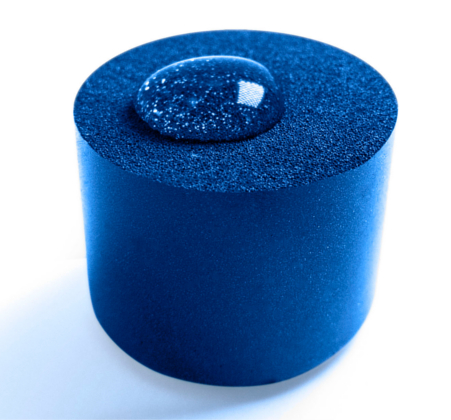

CERAPUR POLYURETHANE FOAM

Sealing material with excellent moisture, dust, noise and vibration protection

-

CLOSED CELL FOAM STRUCTURE

Ideal insulation properties combined with flexibility

-

WAGE SUPPLEMENTS

Contract manufacturing available at Cerocon's german factory

VIDEOS

АУТОМАТСКО ДОЗИРАЊЕ ПЕНЕ

Церацонов систем Церафлов обезбеђује дозирање хомогене полиуретанске пене затворених ц́елија у правој количини, без обзира на то колико је сложен образац дозирања.