MANUAL AND SEMI-AUTOMATIC PICK AND PLACE

FRITSCH MANUAL AND SEMI-AUTOMATIC PICK AND PLACE

Modular manual and semi-automatic assembly systems allow the whole process to be carried out, from the dispensing of solder paste or glue to the insertion of different chips, SO and FP components. Members of the Manipulator placement machine family display the pick and place positions, i.e. they control the whole process, thus guaranteeing the assembly safety of the 100%. The intelligent software and CAD-DATA converter allow a fast and error-free process.

Manipulator implanters are available in several levels of automation, in several different sizes, with variable options to respond to different needs.

- Details

- Parameters

- Options

LM SERIES

- Economical manual transplanters

- Placement camera

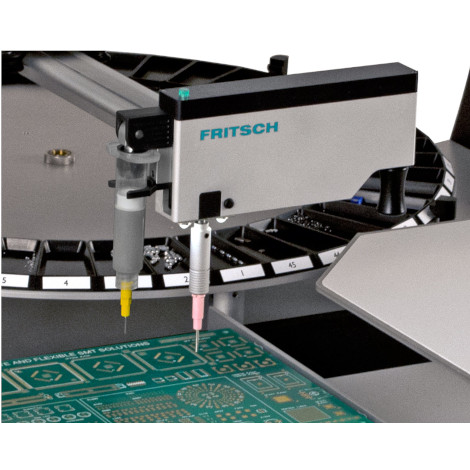

- Automatic carousel

- X,Y and Z axis guidance

- Dispenser option (solder paste and SMT glue)

- LMinline conveyors version is ideal for repair tasks, for example

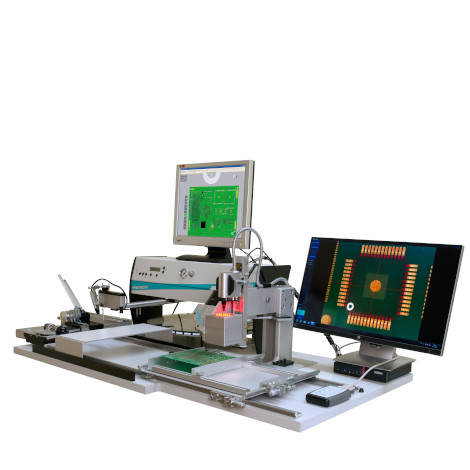

SM PRO SERIES

- Semi-automatic insertion eliminates the possibility of misplacement thanks to the insertion head always moving to the right place

- LED indication of wiring and components makes reading the installation plan unnecessary

- Component translation station

- CAD based implantation program generation

- All options of LM series available (dispenser, carousel, positioning camera)

- XL version also for large 590 x 510 mm panels

MP 904 PLANTER

- Implantation 0201 parts, BGAs for QFN implantation

- Projection positioning

- Micrometer table setting

FEEDER OPTIONS:

- Coil

- Tray

- Rod

- Cargo

-

MP904 STATION

Projection camera for precise insertion of BGA, QFNs, 0201 chip.

-

AUTOMATIC CAROUSEL

Bulk parts can be picked up, the carousel moves according to the insertion program

-

CAD CONVERSION

Conversion of CAD and Gerber data into implantation programs can be done

-

TRANSLATION STATION

Reversal of parts recorded backwards

-

DISPENSER OPTION

Integrated solder paste or SMT adhesive application

VIDEOS

LM SERIES

Manual transplanters

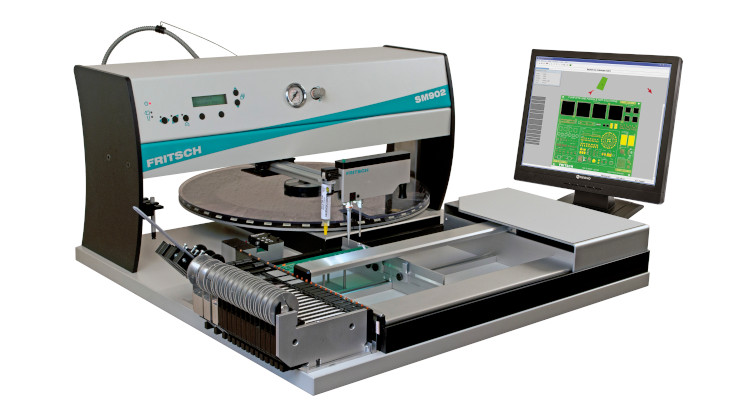

SM902 PRO

Semi-automatic planter with motorised guidance for error-free installation

MP904

Semi-automatic placement machine for Fine Pitch and BGA parts