JET DOSAGE

Non-contact rapid dispensers

For contact dispensing, it is always important to determine the relationship between the dispensing needle and the surface to be dispensed, which is often not easy, difficult to repeat and even time-consuming. With jet technology, however, this is not necessary, saving time and improving quality. With Musashi Jet heads, we can apply the material drop by drop to any smooth, uneven or even hard-to-reach surface.

The Musashi Jet heads can dispense almost any viscosity of material at high speeds, even in very small quantities, be it varnish, gel, grease, glue, solder paste or underfill. The heads are available in integrator-mounted form, table-top robot-mounted and as fully inline dispensing cells.

- Details

- Options

-

- Non-contact dispensing, no need to match dispensing needle and surface

- Fast cycle times, up to 1000 Hz feed rate

- Nanolitre volume also for microdispensing tasks

APPLICATIONS FOR A WIDE RANGE OF MATERIALS AND VISCOSITIES:

-

- Lacquering and underfill

- Solvent paste dosage

- SMT and other adhesives

- Frying

MULTIPLE JET DISPENSING HEADS:

-

- AeroJet - pneumatic dispensing head for almost any material

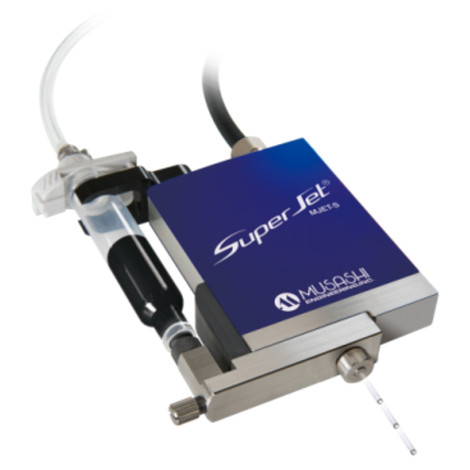

- SuperJet - for quick dispensing of small quantities - underfill, gluing

- SuperHiJet - Dispensing of higher viscosity pastes, gels

- CyberJet - for dosing low viscosity materials

- Head heating unit

- Integrated shot counter

- Can be integrated into target machines or robotic arms

- Available for installation Musashi for desktop and suspended robots

- Musashi also available in automatic cells

-

SuperJet

Up to 555 Hz piezo driven Jet head for quick dispensing and underfilling of small quantities

-

SuperHiJet

Jet-forming of higher viscosity pastes and materials is also possible

-

AeroJet

Universal pneumatic Jet for varnish, solder paste, SMT adhesive or even grease

-

CyberJet

For dosing low viscosity liquids, reagents

-

HotmeltJet

Precision dispensing of hotplates

-

GreaseJet

Complete fattening stations

VIDEOS

SuperJet

Even very small quantities can be dispensed quickly and accurately.

AeroJet

Best seller, versatility for varnishes, SMT adhesives, solder paste or greases.

SuperHiJet

Jet dosing of high viscosity pastes and adhesives is also possible!

CyberJet

Dispensing low viscosity liquids from tubes.

HotmeltJet

Precision dispensing of hot melt adhesives.

GreaseJet

Precision dosing of fats.