ROTATING MACHINE STATUS TEST

For reliable and stable production

Periodic machine condition inspection and monitoring, for example after maintenance, is a priority to ensure stable production quality. ECD is specifically designed for soldering equipment ( reflow furnace and wave soldering) to measure specific properties of the equipment that influence or affect the quality of the process. The MoleMap software can also be used to perform detailed statistical evaluations (SPC module) and generate customised reports.

To use the instruments ECD data logger is necessary!

- Details

WaveRider

- For wave soldering

- Can be used with 6 channel SuperMole Gold2 profilometer

- Waveguide measurement

- Immersion time measurement

- Test panel with bottom, downhole and top sensors to simulate hole filling

- Conveyor speed

- MoleMAP evaluation software

- Palette sizes: Length 305 mm x Height 33 mm x Width 229; 305; 457 mm or custom sizes

OvenRider

- Reflow for furnace

- Can be used with 6 channel SuperMole Gold2 profilometer

- 3 Air sensor (fan sensor)

- 3 convection sensors (heating element test)

- Conveyor speed

- MoleMAP evaluation software

- Palette sizes: Length 305mm x Height 33mm x Width 168; 305; 458mm or custom sizes

- OvenChecker 3 channel version

- MegaRider 20 channel version

Fluxometer

- Waveguide for fluxer unit

- Test paper suitable for alcohol and water-based fluxes

- Test-fit design

- Simple fluxer setup

- Reduces production costs, scrap rates and rework

- Palette sizes: Length 305mm x Height 33mm x Width 168; 305; 458mm or custom sizes

-

OvenRider

Reflow furnace with test palette for convection and air temeprature sensors

-

OVENRIDER IN THE OVEN

Available in several sizes

-

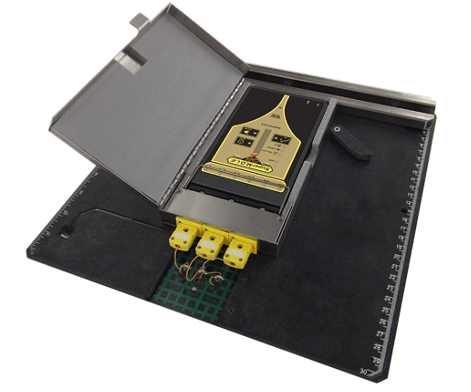

WAVERIDER

Machine condition monitoring palette with wvae height, immersion time, wave pair

-

WAVERIDER IN THE MACHINE

Available in several sizes

-

FLUXOMETER

Spread pattern and hole runout control palette

-

FLUXOMETER IN THE MACHINE

VIDEOS

ECD MOLE FAMILY OF PROFILOMETERS