CNCell

High capacity with flexibility

CNCell is the flagship module of the Scheugenpflug portfolio. This automatic dosing machine is capable of large capacities with high quality, even in the case of large mixture production. The equipment is available as stand-alone, in-line or with a rotary table. Many options are available, such as a camera recognition and inspection system, code reading, plasma cleaning, implantation, screwing or even marking. We can also offer several types of ovens with thermal convection or UV drying to complement the dosing machine.

- Details

- Parameters

- Options

- Ease of use and programmability

- Precise 3-axis or 4-axis CNC system (20 micron setting accuracy - X; Y axis)

- Speed 160-800 mm/sec

- Step or servo motor

- Beckhoff computer-based industrial control

- Choice of material handling solutions: one or two drawers or inline rotary table design

- DosP and DosGP dosing heads can be installed

- Scheugenpflug material preparers (A90; A280; A310; LP804) can be connected

- Needle calibration unit - needle deflection compensation

- Joystick – for easy manual control

- Parking glass - needle asphyxiation prevention

- Pot life calculation - Anti-drying mixer

- Integrated weight measurement - planned control of the dosage amount

- Workspaces of different dimensions can be created (1000 x 8000 mm, 1400 x 1200 mm)

- Heating of products, pallets, dosing heads or mixers

- Product position or type sensor

- Camera system for product recognition or dosing quality control

Dimensions S × M × M:

- 800 x 800 x 2160 mm

- 1000 x 800 x 2160 mm

- 1000 x 1000 x 2160 mm

- 1200 x 1000 x 2160 mm

- 1200 x 1200 x 2160 mm

- 1400 x 1200 x 2160 mm

Power supply: 3 x 400 V~, 50/60 Hz, CEE 16 A

Additional and supporting dosing functions are available:

- Ovens with convection or UV drying

- Assembling, inserting or screwing modules

- Camera control

- Plasma cleaning, surface treatment

-

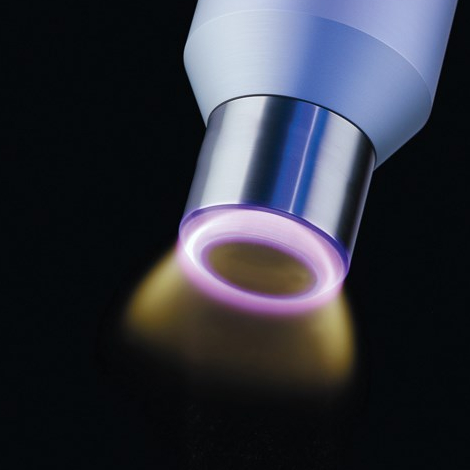

Plasma

Several options for plasma surface pretreatment can be integrated into the machine.

-

Camera

Built-in visualization for position recognition or inspection.

-

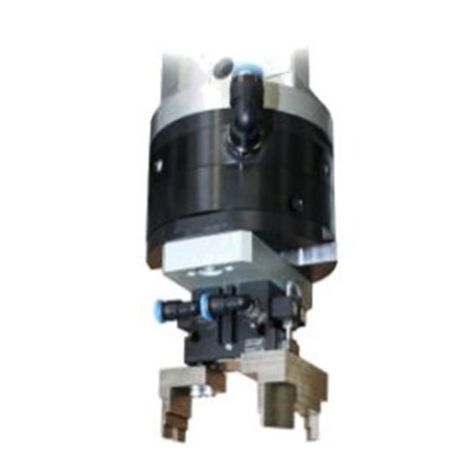

Gripper

Individually designed components can be incorporated into the dosing machine.

-

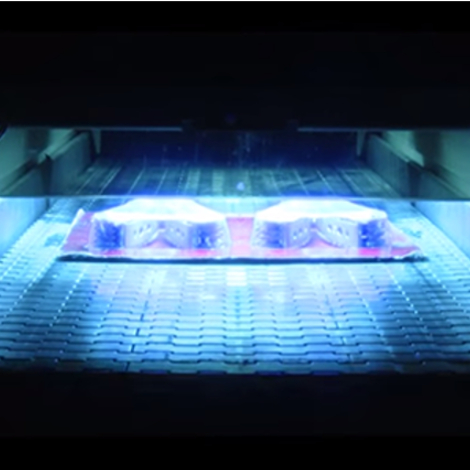

Drying

UV and convection ovens for proper curing.

VIDEOS

Dosing with CNCell

Fully automatic high capacity dosing system with individually extended options.