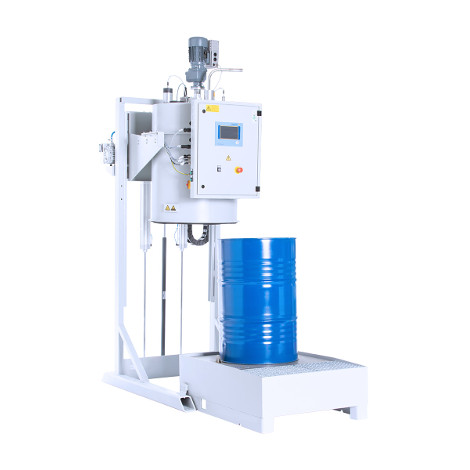

BARREL AGITATOR STATION

The barrel maker

The Scheugenpflug drum mixing station provides a unique solution on the market for the de-bubbling, homogenisation and air and moisture free storage and preparation of 200 litre drum materials (e.g. polyurethanes). Ideal for applications where material loss is significant. The barrel mixing station can be directly connected to LP804 or LP804 A310 preparation unit or even the Scheugenpflug for dosing heads, and can also be controlled by its own SCP210 unit.

- Details

- Parameters

- for the preparation and handling of 200 litre drums

- Storage under vacuum for moisture sensitive bubble-free materials

- Low to medium viscosity, even for abrasive materials

- Continuous mixing to prevent separation of the filled materials

- Material viscosity adjustment with adjustable heating up to 80°C

- A310, LP804 or even dispensing head can be connected directly to the unit

- Dimensions (W × D × H): 1050 × 3000 × 1700 mm

- Weight: 800 or 1000 kg

- Capacity: 850 kg

- Power supply: 3 x 400 V~, 50/60 Hz, CEE 16 A

- Ejector: 12 l/min (at 6 bar)

- Evacuation: none or 283 l/min

- Mixing speed: 0- 60 rpm

- Heating up to 80°C

-

BARREL AGITATOR STATION

Automatic barrel change

-

BARREL AGITATOR STATION

Mixing, venting, heating and level measurement

VIDEOS

LOAD PREPARATION STATION

A unique solution for dispensing large quantities, for the preparation and storage of materials that are sensitive to moisture or separation.