Ceracon Stack is the leading model from the manufacturer thanks to its extreme space saving and efficiency. In this machine, 6 to 6 different temperature zones per ascending and descending branch can be configured, allowing even the most complex thermal profiles to be realised. The machine's conveyor trays can be scaled to the product to be handled, allowing maximum product density to be achieved in the machine, whether the task is the production of thin films or large automotive assemblies.

HEAT TREATMENT, CURING

This Ceracon furnace is an extremely space-saving device for heat treatment and curing tasks compared to, for example, tunnel furnaces. The tower height, ascending and descending branches can be individually designed for the heat profile and production area.

In the Ceracon Paternoster oven, the products travel in a vertical circle in gondolas, just like in traditional paternosters.

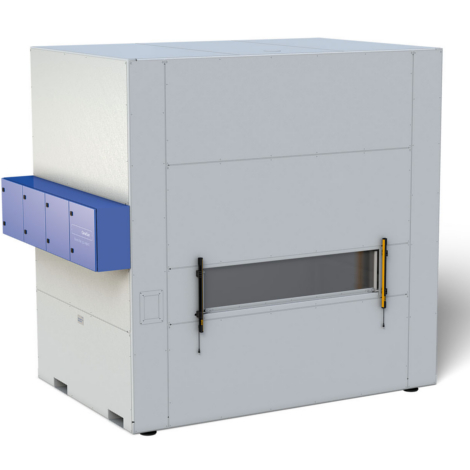

CeraTherm Batch is a robust, industrial-grade offline batch furnace for small to medium volume heat treatment applications. The 720 litre convection hot air heated chamber in the machine is responsible for the proper heat treatment performance.

Our CeraTherm Tunnel horizontal continuous tunnel furnaces provide a precise yet economical automatic heat treatment solution for a variety of production needs.