Yamaha will start selling the YRM20 equipped with the most innovative technologies from April 2020. In terms of its speed and capabilities, it serves the high-mix, high-volume market in a similar way to its predecessor.

Pick and Place

Yamaha's philosophy is to launch products that always offer something special in their category compared to competitors. Whether it's the outstanding speed, the wide range of parts that can be installed, or simply the usual Japanese quality, affordability and, last but not least, economical operation. What we can say with certainty is that those familiar with Yamaha implants were reluctant to switch to others, and those who were unfamiliar with them quickly fell in love with them. Try it yourself!

The implant machines listed below are part of the Yamaha Total Line Solution, which includes paste printers, glue or paste dispensers, 3D SPI, pick & place and 3D AOI machines from one source from one manufacturer!

The flagship model of the Yamaha pick and place portfolio is the ISM series. Among them, the YSM20R planters combine the speed and versatility of planting thanks to the high position of the feeder and bed and several types of planting heads. Type YSM20RV with its large working space is an excellent solution for particularly large applications such as LED.

Yamaha completes its portfolio with the Sigma series developed in Japan, but operating under the Hitachi name. Similar to the YSM20R type, it was sharpened for high mix and/or high volume production without compromise.

From our wide range of planters, this is our entry-level equipment, which differs in price and speed from its big brothers. It is equivalent in quality, reliability, accuracy and usability.

The YSM40R is Yamaha's smallest space-saving but fastest planter. This is the solution to compensate for the endless reduction in cycle time and to meet the future needs of mass production, both in terms of planting and quality.

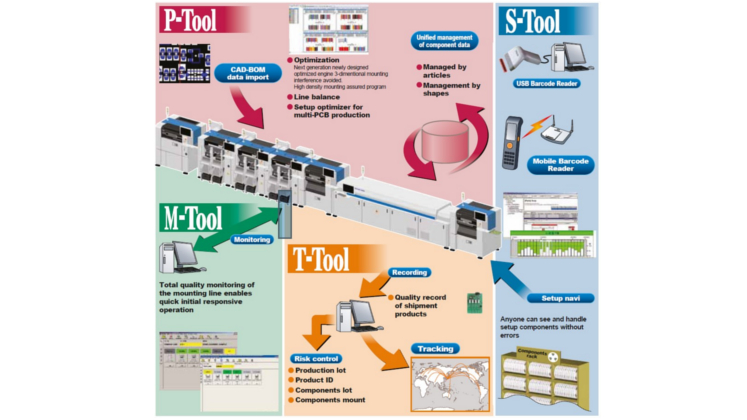

The special feature of YAMAHA machines is the complete integration of the self-produced paste printer and AOI equipment into the software package for production support. With this concept, production line handling, the number and reaction time of micro-stops, and even the production cycle time can be significantly reduced. The YAMAHA solution is made with special functions such as offset printing and bad mark feedback from the pattern printer to the implanter, or implantation error feedback from the AOI to the implanter.